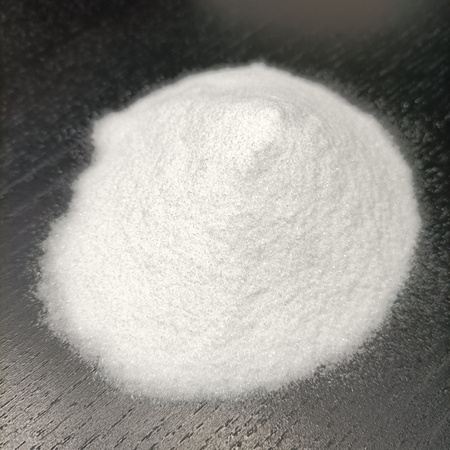

Soda

Soda is high quality product used for sodablasting, cleaning , contamination removal, cause no hazard to workers and the environment . Soda shows good solubility, liquidity in solution and high rate of whiteness. In the process of sodablasting soda is used as an alternative to traditional methods of coatings removal with chemical preparations and gentle, ecological abrasives like: wallnut shells, plastic, sponge abrasive media, glass granulate, dry ice, glass and ceramic beads. In the process of coatings removal soda is used in wet and dry sodablasting. Soda when hitting the surface, breaks down into small particles, which does not emit hazardous dust, because it does not contain free silica, heavy metals and toxins.

Soda is used for sodablasting : a non-invasive cleaning of wood, stone, glass, aluminium, steel, stainless steel, plastic, rubber, bricks, laminates without gloss and structure damage, without roughness. Soda removes varnish, dirt such as lubricants, oils, paints, burnt, graffiti, grease, scale formation and other deposits and moulds without damage to the surface. Soda is non-sparking abrasive and it does not cause heating and deformation of details. Soda is used in fire restoration smell, also removes odours. Sodablasting guarantees fast cleaning, wet or dry.

| AVAILABLE SIZES |

80/200 Mesh – fine |

|---|

Specification

- Chemical composition: NaHCO3 > 99.0-100%

- Shape: white crystalline grains

- MOH’S hardness – 2,5

- Bulk density – 1.40 g/cm3

- Packaging: bags 25 kg.